Powder Metal Sintered Chikamu base vharafu yeShock Absorber

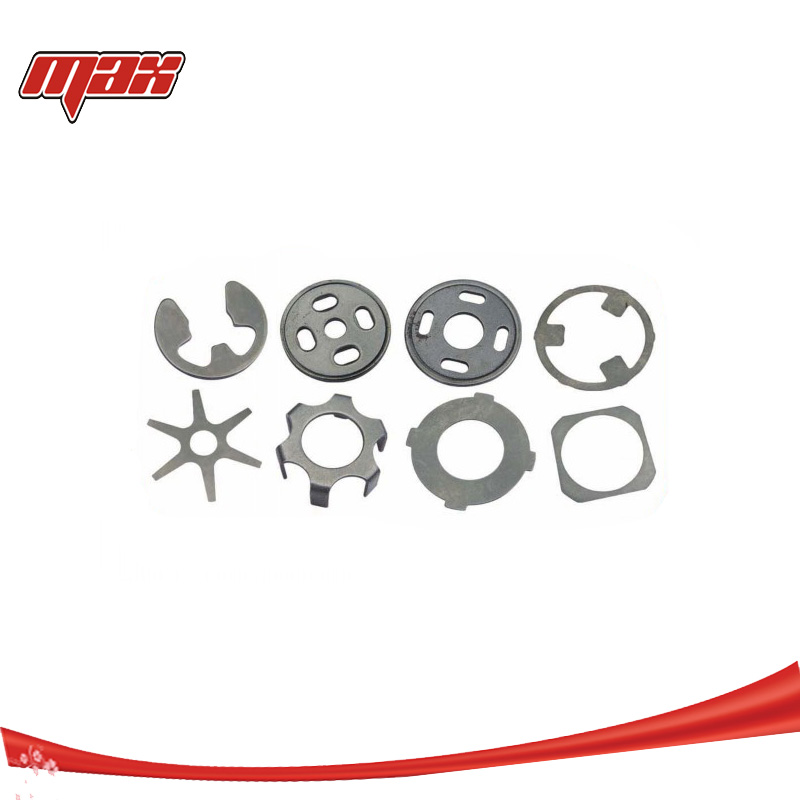

Product features:

Iyo piston nevharuvhu yepasi zvinonyanya kupa kunyorovesa kwekuvhunduka, tsvimbo inotungamira inotungamira yekufamba kwepiston tsvimbo.

Max Auto ndiyo yepamusoro kugadzira iyo simbi yemagetsiSintered parts, kunyanya kushandiswa kwema components ekuvhundutsa .

Tekinoroji maitiro: kusanganisa hupfu - kuumba - sintering - kuchenesa -Steam kurapwa - Bending-Press bushing-Kuonekwa kwekutarisa, kurongedza.

Kusanganisa poda: Fe - C - Cu hupfu nehupamhi density sieve kubvisa tsvina, otomatiki yekusanganisa muchina 360 ° inotenderera anopfuura maawa mana, ita kuti zvinhu zvisanganiswe zvakaenzana.

Kuumba: chaiyo mold ine otomatiki CNC hydraulic Press kuti ive nechokwadi chekuti density yezvikamu zvese zvinosangana nezvinodiwa maitiro mushure mekudzvanya.

Sintering: chigadzirwa chinodzorwa net mambure bhandi rudzi sintering furnace, iyo inova nechokwadi chemichini yezvivakwa uye kuoma kwezvigadzirwa kuzadzisa zvinodiwa zvehunyanzvi.

Kunyudzwa kwemafuta: isa chigadzirwa mumudziyo wakanyanya kudzvanywa kuitira kuti mafuta apinde zvizere mukati mechigadzirwa pores uye kudzivirira ngura yekutevera kutenderera.

Plastiki: chaiyo mold ine yakazara otomatiki CNC hydraulic press, density yechigadzirwa uye michina zvivakwa zvinowedzerwazve kuvandudzwa mushure mekudzvanya, uye zviyero zvinosangana nezvinodiwa zvekudhirowa.

Machining: kupedzisa gomba, groove uye mamwe mashoko echigadzirwa.

Kuchenesa: iyo mesh bhandi inotora ultrasonic yekuchenesa muchina kubvisa tsvina uye mafirita esimbi.

Steam kurapwa: chigadzirwa chinobatwa nemhepo muchoto chemagetsi, iyo inovandudza michina yezvigadzirwa, uye iyo yepamusoro oxidation layer inobatsira kudzivirira ngura.

Packing: iyo piston yakafukidzwa neakazara otomatiki nhamba yekudzora muchina unovhara PTFE lubrication bhandi.

Dzvanya bushing: yakatsikirirwa muDU bushing.

Kuongororwa kwekuonekwa, kurongedza.

Specification :

| Product Details | |

| Product Name | Powder Metal Sintered Chikamu cheShock Absorber |

| Material | (MPIF 35) FC-0205 (DIN 30910-4) Sint C10, Fe, Balance, Cu 1.5-3.9%, C 0.3-0.6% |

| Density | 6.4-6.9 g/cm3 mushure mehupfu oxidation |

| Kuoma | 60-115 HRB, kurodha 1 kN, dhayamita yebhora 1/16 ″ |

| Surface Treatment | Steam oxidation, maawa maviri, Fe3O4: 0.004-0.005mm, dhigirii ye oxidation 2-4% |

| Kushivirira Kusingataurwi | ISO 2768 – m/H14, h14, +- IT14/2 |

| Apperance | Hapana kukoromoka, kutsemuka, exfoliation, voids, looseness, simbi pitting uye kumwe kukanganisa |

| Process Flow | Kusanganiswa kwehupfu - Kugadzira - Sintering - Kuiswa kwemafuta - Kukura - Ultrasonic kuchenesa – Steam oxidation – Oiri impregnation – Final kuongorora - (+ DP4 bushing / +PTFE bhendi) Kurongedza |

| Application | Yemotokari, mudhudhudhu uye bhasikoro kuvhunduka kunobata |

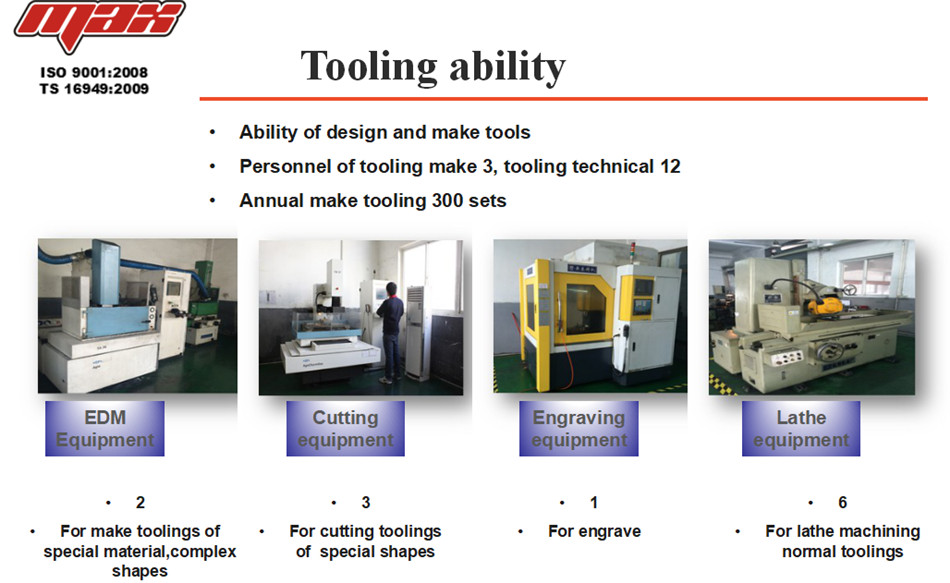

| Zvatinazvo: | 1. Kupfuura zvazvino 3000 molds, chengetedza yako mold mutengo 2. ISO/TS 16949:2009 chitupa 3.Competitive mutengo 4.Strictly quality control capacity of APQP,FEMA,MSA,PPAP,SPC |

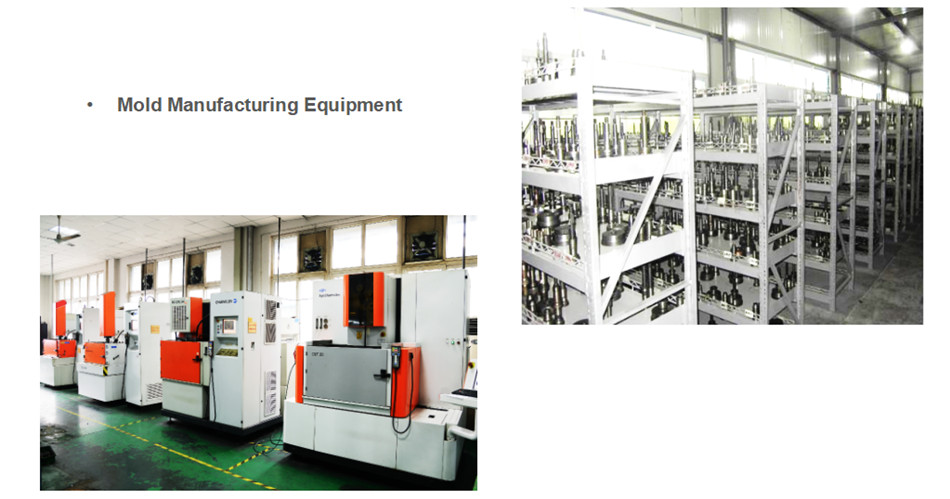

Zvishandiso zvekugadzira

Examination Facilities