Wepamusoro Mugadziri wechrome tsvimbo nemutengo wakanaka wakagadziridzwa saizi

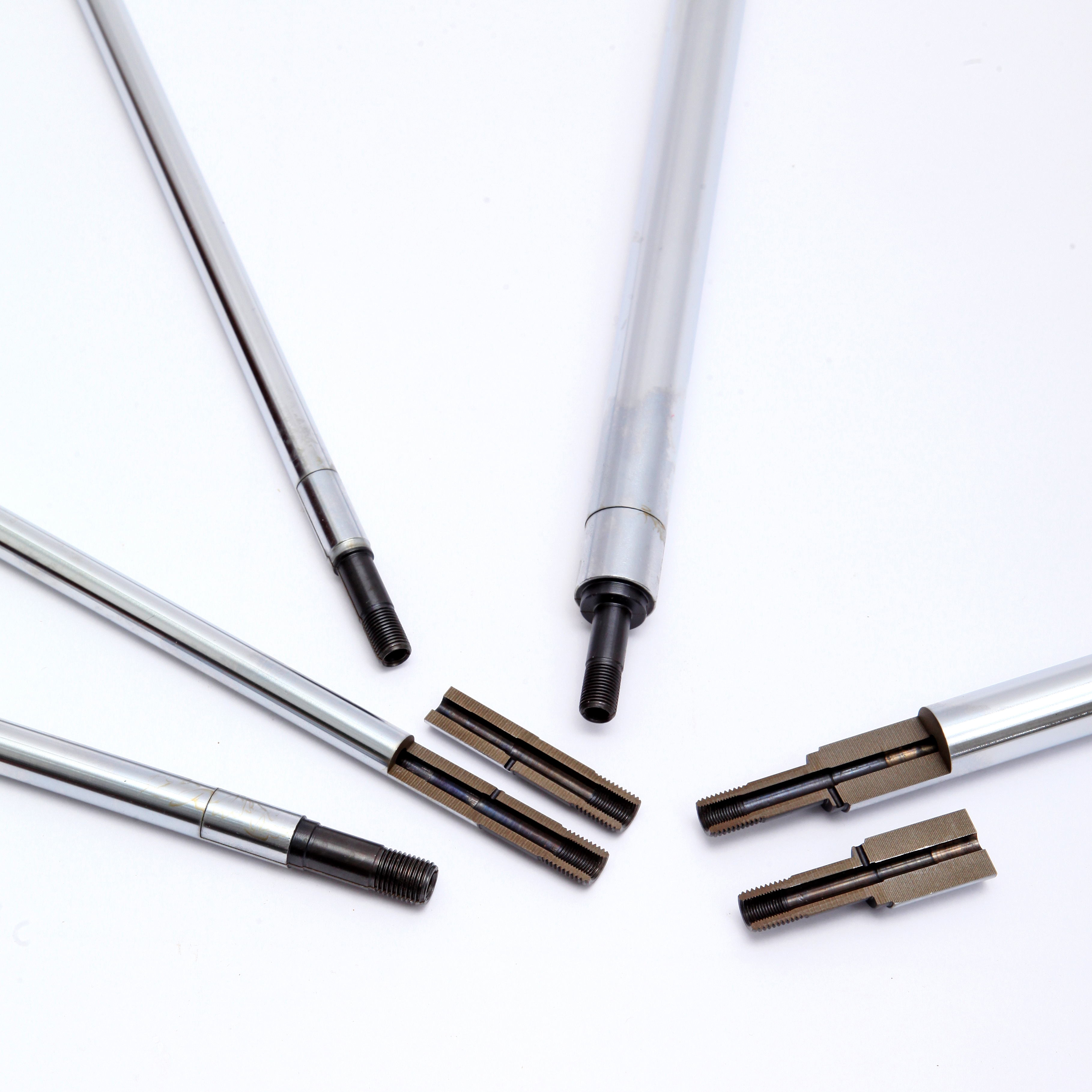

| Outer Diameter: | Ø 6mm-35mm |

| Hurefu Hwose: | 100mm -650mm |

| Steel Material: | SAE1035/SAE1045 |

| Chrome Kukora: | 10~25 μm |

| Chrome Kuoma: | 900 HV Min |

| Hushasha: | Ra 0.1 Micron Max |

| Kururama: | 0.02/400mm |

| Goho Simba | Maererano nesimbi yezvinhu uye zvinodiwa nevatengi |

| Tensile Simba | Maererano nesimbi yezvinhu uye zvinodiwa nevatengi |

| Elongation | Maererano nesimbi materia |

| Bend Test | Maererano nezvinodiwa nevatengi |

| Supply condition: | 1. Yakaoma Chrome Yakaputirwa |

| 2. QPQ Kurapa | |

| 3. Induction Yakaomeswa | |

| 4. Dehydrogenation & Tempered

|

Application: Chrome Piston tsvimbo inonyanya kushandiswa mu hydraulic pneumatic, engineering michina, kugadzira mota nepiston tsvimbo, dhiraivha mbiru epurasitiki muchina, kurongedza muchina, kudhinda muchina, roller, machira emuchina, ekufambisa muchina ane axis, mutsara inofamba ine mutsara optical axis.

I. process sumo.

Thepiston tsvimboyakaoma chromium plating pasimbi substrate pamusoro yakavharidzirwa nehupamhi hwechromium plating uye ukobvu hwayo hunowanikwa mune 10 kusvika 30 microns, uchishandisa maitiro echromium anonatsiridza mashandiro ezvikamu, sekuoma, kusapfeka, kuramba kupisa uye kusagadzikana nekuora.

Iyo maitiro maitiro eiyo yakaoma chrome yakapfava piston tsvimbo:

1) iyo cathode ikozvino inoshanda yakakwira se25% ~ 35%, uye deposition rate inokurumidza kwazvo.

2) kuomarara kwakanyanya (900 ~ 1200HV), yunifomu uye dense network yakatsemuka, yakanaka abrasion kuramba; Microcracks inogona kugadzirwa, uye huwandu hwe microcracks hunogona kusvika 800-2000 zvidimbu / cm (maererano nezvinodiwa), uye kuvandudza anti- ngura kugona.

3) kugona kupararira kwakanaka kwekugezera yekugezesa, kukora kweyunifomu yejasi, hazvisi nyore kugadzira chiitiko che rough blister tumor, uye kutaridzika kwechromium layer inopenya uye yakatsetseka;

4) iyo yekupfekedza ine simba rakasimba rekubatanidza ne substrate, uye pretreatment yakafanana neyechinyakare tekinoroji, uye kushanda kuri nyore pane yechinyakare maitiro;

5) zvinyorwa zve trivalent chromium mubhati zvinobvumirwa kuva zvakafara, uye kazhinji hazvidi kurega electrolysis ye trivalent chromium;

6) mhinduro yeplating haina fluoride, hapana zvisingawanzo zvinhu zvepasi, uye hapana kuora kwechishandiso pasina simba rakaderera.

2. Process flow.

1).Maitiro ekuyerera kwe hydraulic piston rod.

Kubatanidza tsvimbo uchishandisa makumi matatu neshanu simbi, kugadzira tekinoroji: inotonhora-inodhonzwa ichiita inotenderedza inoenderera yepakati frequency induction kuomesa, cylindrical kugaya, yakanaka kugaya cylindrical a yakanaka kugaya cylindrical shearing chikamu.pakupedza plating chromium kune hydrogen tempering shearing chikamu. Kuti uvandudze kunaka kwepamusoro uye kuramba kwecorrosion yepiston rod, super finishing process yakawedzerwa pamberi pe chrome plating.

2).Piston tsvimbo yeplating process.

Ongorora usati waputirwa - paki inorembera gadziriso - makemikari degreasing, magetsi ekusimudza mafuta - mvura - activation pickling - kugeza mvura- nguva yacho, piston rod chromium plating, kudzoreredza mvura - kugeza mvura - kuburitsa yakaturika gadziriso - kuongorora.